Multi Purpose Wheel Chair for Disabled Persons

Table Of Contents

Chapter ONE

1.1 Introduction1.2 Background of Study

1.3 Problem Statement

1.4 Objective of Study

1.5 Limitation of Study

1.6 Scope of Study

1.7 Significance of Study

1.8 Structure of the Research

1.9 Definition of Terms

Chapter TWO

2.1 Overview of Assistive Technologies2.2 History of Wheelchairs

2.3 Types of Wheelchairs

2.4 Design Considerations for Wheelchairs

2.5 Technology Integration in Wheelchair Design

2.6 User Experience and Feedback

2.7 Innovations in Wheelchair Mobility

2.8 Impact of Wheelchair Design on Accessibility

2.9 Challenges in Wheelchair Development

2.10 Future Trends in Wheelchair Technology

Chapter THREE

3.1 Research Design3.2 Data Collection Methods

3.3 Sampling Techniques

3.4 Research Instruments

3.5 Data Analysis Procedures

3.6 Ethical Considerations

3.7 Pilot Study

3.8 Reliability and Validity

Chapter FOUR

4.1 Overview of Findings4.2 Participant Responses

4.3 Analysis of Data

4.4 Comparison of Wheelchair Models

4.5 User Satisfaction Levels

4.6 Recommendations for Improvement

4.7 Impact on Mobility and Independence

4.8 Future Research Directions

Chapter FIVE

5.1 Summary of Findings5.2 Conclusion

5.3 Implications of the Study

5.4 Contributions to Knowledge

5.5 Recommendations for Practice

5.6 Areas for Future Research

Project Abstract

Abstract

The effective design of multipurpose chair for disabled person is to reduce the transferring time inside the home. The design is also used for sleeping, eating, drinking, reading and writing is possible for in a single design of chair. There are salient features which are added with the design of chair to improve the performance of the existing design. The distance between the front and rear axle distance can be adjustable for threaded rod and fixed bolt. The vertical height also adjustable for with respect to our requirement. The adjustable threaded rods are rotated with respect to the battery operated motor. The forward and reverse direction moment can be possible by operating the needles. The direction also controlled by the front wheel with respect to needle movement. The sliding backbone movement bed is possible by using connecting lever. The frame is made of strong materials. The design of all the operation occurs with respect to needle movement and connecting lever.

Project Overview

Introduction

In our day to day life lot of innovative machines and devices are coming. The innovations are to reduce usage of manpower and increasing the productivity in all fields. The main reason for new machines is to create the human comfortable zone. The transportation can be easily by using cycles, bikes, cars and air craft. But the normal human being can be take any decision at any places. But the disabled persons are directly depends on others and self-transportation is not possible. So it can be rectified that special care takers are selected for this places. The disabled persons can’t able be move from one place to another place by their own. The disabled persons sit in the same place for full day, month and year. It will create a impact that is very dangerous. All the disabled persons are individually strong with their areas such as drawing, logical thinking, reading, writing and listening. The disabled person brain is capable to capture some things in all the kind of situations. The advanced treatments are very helpful to cure the problems. But some of the problems are not rectified. So the disabled person is directly depended on parents, friends and care takers.

Objectives:

To prepare a design of wheel chair for a disabled person with maximum specifications .The application of advanced components with minimum cost. To prepare a design for low cost wheel chair for disabled person .To design additional parts of the chair and to create the stored boxes to store useful things in the design.

Features

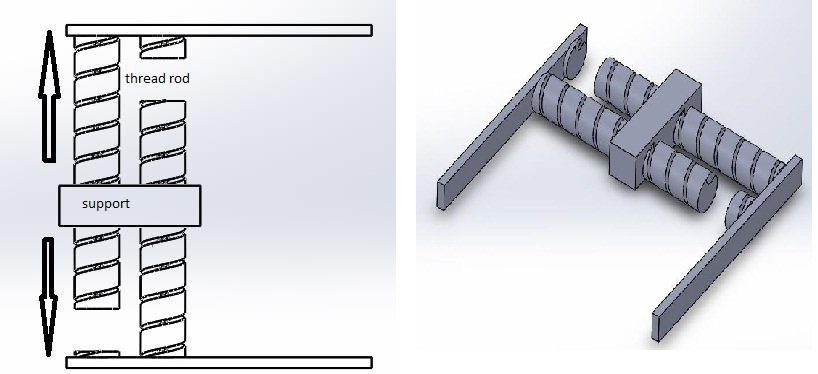

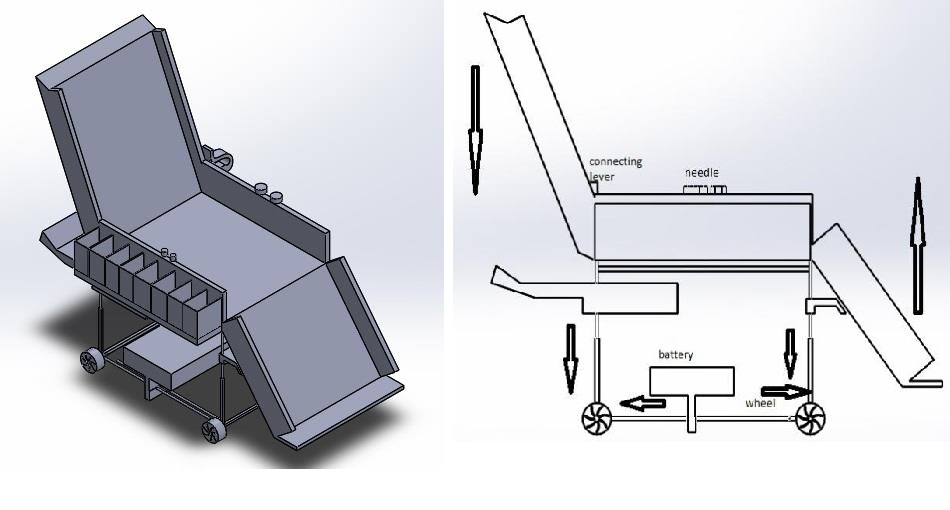

The special design of transporting vehicle is for disabled persons .The vehicle consist of four wheels and the each wheels are of same diameter. The distance between the front and the rear wheels are in same distance. The chair bottom layout consist of square section. The main specification of the design is used to the transporting chair also used for sleeping bed, dining table and laptop table. The various expandable and adjustable joints are very helpful to produce the motion with respect to our requirement. In the design of the system is the disabled person is easy to move at any place of home and does not completely depending on care takers.Fig 4.1 and 4.2 top and isometric view of horizontal adjustment

The horizontal distance can be easily adjustable by using thread covered the fixed bolts. The four threaded rods are attached with two front axle and two attached with rear axle. An intermediate component is used to hold the threaded bars and battery. The battery is operated by the motor. The center distance of the front and rear axle is increased at double times of initial chair position. So the foot stand is automatically lifted by the certain angled stands. The stands are not lifted easily. But the horizontal motion is automatically reaction is possible. After the complete horizontal distance movement of the backbone sliding bed is gradually in down position by using connecting lever. The lever is operated by the left hand with the minimum pressure. The pressure is directly applied on the shaft o the motor. So the sliding bed is gradually to reach in horizontal position. The total distance is directly proportional to the height of the human being bed.

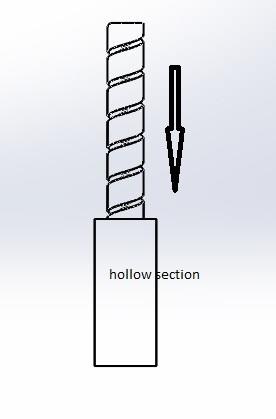

The vertical distance also adjustable for a short distance by using hollow internal threaded rod and top of the external threaded rods. The rods threads are mesh with one another, uniform deviation is possible. The vertical distance can be reduced in half of the original height. Because that the distance bottom of the bed is in contact with the battery top. The complete revolution of the threads of all the rod is automatically the motor is rotated with the help of bearing. So there no power transmission is possible. The bottom of the front axle wheels are only in direction control and the rear wheel drive is applicable for the chair design. The front and rear axle distance can be controlled by the help of electric motor. But the distance between two wheels are not changed.

The right side of the chair is provided with two needles. The front needle is to control the forward and reverse motion of the design and the other needle is provided for direction control of the left and right directions. The left hand of the chair is also provided with two needles. The front one is to increase and decrease the horizontal distance between the front and rear axle and the other needle is provided for adjust the vertical distance between the top of the battery and the bottom of the bed. The connecting lever is provided for lift and decrease the backbone bed of the chair. In the design of chair all the motions can be possible by battery operated. There is no need for human power. The additional features are added to the wheel chair is near the right needle the number of boxes are provided for placing the things such as remote, water bottle, pen and mobile phones. The bottom of the sitting bed, a tray is provided for to protect the important documents, laptop and books. Whenever it is required and the other time is closed. The top of needle is additional thick sheet is provided for the usage of the dining table and writing desk.

Detail Design

Side View of Adjustable Design

Blazingprojects Mobile App

📚 Over 50,000 Project Materials

📱 100% Offline: No internet needed

📝 Over 98 Departments

🔍 Software coding and Machine construction

🎓 Postgraduate/Undergraduate Research works

📥 Instant Whatsapp/Email Delivery

Related Research

Optimization of Production Line Layout using Simulation Techniques in an Automotive ...

The project titled "Optimization of Production Line Layout using Simulation Techniques in an Automotive Manufacturing Plant" focuses on enhancing the ...

Optimization of production scheduling using advanced algorithms in a manufacturing e...

The project topic, "Optimization of production scheduling using advanced algorithms in a manufacturing environment," focuses on enhancing the efficien...

Application of Lean Six Sigma in Improving Manufacturing Processes in the Automotive...

The project topic, "Application of Lean Six Sigma in Improving Manufacturing Processes in the Automotive Industry," focuses on the implementation of L...

Optimization of Manufacturing Processes using Artificial Intelligence Techniques in ...

The project topic "Optimization of Manufacturing Processes using Artificial Intelligence Techniques in Industrial and Production Engineering" focuses ...

Implementation of Lean Six Sigma in a Manufacturing Process for Quality Improvement ...

The project topic, "Implementation of Lean Six Sigma in a Manufacturing Process for Quality Improvement and Waste Reduction," focuses on the applicati...

Optimization of Production Line Layout Using Simulation Techniques in a Manufacturin...

The project topic "Optimization of Production Line Layout Using Simulation Techniques in a Manufacturing Industry" aims to address the critical aspect...

Optimization of Production Scheduling in a Manufacturing Environment using Machine L...

The project "Optimization of Production Scheduling in a Manufacturing Environment using Machine Learning Algorithms" aims to address the challenges fa...

Implementation of Lean Six Sigma in a Manufacturing Industry to Improve Production E...

The project topic "Implementation of Lean Six Sigma in a Manufacturing Industry to Improve Production Efficiency" focuses on the integration of Lean S...

Implementation of Lean Manufacturing Techniques in a Manufacturing Company to Improv...

The project topic "Implementation of Lean Manufacturing Techniques in a Manufacturing Company to Improve Productivity and Quality" focuses on the appl...