Fatigue Testing Machine for Composite Leafspring

Table Of Contents

Chapter ONE

1.1 Introduction1.2 Background of Study

1.3 Problem Statement

1.4 Objective of Study

1.5 Limitation of Study

1.6 Scope of Study

1.7 Significance of Study

1.8 Structure of the Research

1.9 Definition of Terms

Chapter TWO

2.1 Overview of Composite Materials2.2 Historical Development of Composite Leaf Springs

2.3 Properties of Composite Leaf Springs

2.4 Manufacturing Processes of Composite Leaf Springs

2.5 Benefits and Challenges of Using Composite Leaf Springs

2.6 Applications of Composite Leaf Springs

2.7 Comparative Analysis with Traditional Leaf Springs

2.8 Future Trends in Composite Leaf Spring Technology

2.9 Case Studies on Composite Leaf Spring Implementation

2.10 Environmental Impact of Composite Leaf Springs

Chapter THREE

3.1 Research Design3.2 Sampling Techniques

3.3 Data Collection Methods

3.4 Data Analysis Techniques

3.5 Research Instruments

3.6 Ethical Considerations

3.7 Validity and Reliability

3.8 Research Limitations

Chapter FOUR

4.1 Analysis of Data4.2 Interpretation of Results

4.3 Comparison with Research Objectives

4.4 Discussion on Key Findings

4.5 Addressing Research Questions

4.6 Implications of Findings

4.7 Recommendations for Practice

4.8 Suggestions for Future Research

Chapter FIVE

5.1 Summary of Findings5.2 Conclusion

5.3 Contributions to Knowledge

5.4 Practical Implications

5.5 Recommendations for Further Action

5.6 Reflection on Research Process

5.7 Areas for Future Research

5.8 Final Thoughts

Project Abstract

Abstract

A fatigue is a failure of material or machine due to the action of repeated or fluctuating stress on a machine member for some number of times. This failure begins with a small crack. The initial crack is so minute that it cannot be detected by the naked eye and is even quite difficult to locate in a magniflux or x-ray inspection. The crack will develop at a point of discontinuity in the material such as a change in cross section, a keyway, a hole or a notch. Less obvious points at which fatigue failure are likely to begin are inspection or stamp marks, internal cracks or even irregularities caused by machining. Once a crack is initiated the stress concentration effect becomes greater and the crack progresses more rapidly. A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. Leaf springs absorb the vehicle vibrations, shocks and bump loads (induced due to road irregularities) by means of spring deflections, so that the potential energy is stored in the leaf spring and then relieved slowly. Ability to store and absorb more amount of strain energy ensures the comfortable suspension system.

The spring is mounted on the axle of the vehicle. The entire vehicle load rests on the leaf spring. The front end of the spring is connected to the frame with a simple pin joint, while the rear end of the spring is connected with a shackle. Shackle is the flexible link which connects between leaf spring rear eye and frame.Project Overview

Introduction

Fatigue testing machine is used to determine the fatigue life or fatigue strength of a material. An overlook to the broken parts in most of the scrap will show that almost all failures occur at stresses below the yield strength of the material. This complex phenomenon is known as “Fatigue”. Fatigue is responsible for 90% of the failures that occur in an industry. In the 19th century, it was considered mysterious since a fatigue fracture did not exhibit any visible plastic deformation, this lead to the belief that fatigue was an engineering problem. A major breakthrough in the understanding of the process of fatigue failure happened in the 20th century with the help of more powerful tools such as computer, powerful microscopic instrument, after which fatigue was not considered as an engineering problem but as both material and design phenomenon.

The idea behind this work is not to provide answers to the unanswered questions, but to solve the difficulty in answering them from a different perspective. This involves defining the unpredictable nature of fatigue failure by conducting tests on various specimens and explain the known techniques of fatigue testing. In the science of materials, fatigue is a phenomenon of weakening of a material caused by repeated application of loads. It is the progressive, unpredictable and structural damage that take place when a material is subjected to cyclic loading.

The nominal maximum stress values that actually cause the material to fail may be much lower than the strength of the material typically quoted as the yield strength or ultimate strength. If the applied loads are greater than a certain threshold value, then microscopic cracks will begin to form at the stress concentrated areas such as grain interface or where there is surface defects. Eventually a crack will reach a critical size, the crack will expand at a faster rate, and the structure will fail.

Objectives:

Main aim of this project work is to design and fabrication of Fatigue Testing Machine which is capable of testing the fatigue life of various samples of fabricated composite leaf springs for Automobile application. Also with the result of each test carried out with this machine, the fatigue life of various fiber reinforced composite materials can be obtained and fatigue failure be guarded against in optimum manner.

ï‚· To design the fatigue tester and it’s components

ï‚· To fabricate the fatigue testing machine

ï‚· To test the fatigue strength of the composite leaf springs

ï‚· Analysis on the fabricated leaf spring

Methodology:

The fatigue testing machine consists of the following components:

ï‚· A HP electric motor 2

ï‚· Flange, connecting rods.

ï‚· Dead weight

ï‚· Plummer blocks

ï‚· Digital counter

ï‚· Variable speed control

ï‚· Specimen ( leaf spring)

ï‚· Bearing

Flange and connecting rods

These are used to have rotary motion and convert it to vertical straight-line motion. So that stroke of required dimension can be achieved. For this an eccentric hole is made on the flange, on which by some manufacturing processes (welding, threading, drilling) connecting rod fixed. The length of eccentricity, length of the connecting rod influences the stroke length. So its important to have much care about the design parameters of these things.

Bearing:

To allow free motion of connecting rod without any interruption, while achieving the strokes on leaf spring.

Plummer block:

In order to balance the rotating masses of high weight capacity by absorbing the vibrations induced during the stroke operation.

The particular bearing used in this project is the single, row, deep; groove bearing that can take both radial load andsome thrust load. The bearing is shouldered in a housing made of cast iron to secure adequate support for the bearingand resist the maximum thrust load.

Digital counter:

These are more important for the ease of analysis. One of these is used to display the number of cycles completed and other is to stress induced for every cycle. These readings make the working of machine much précised.

Variable speed control

Speed of the motor is adjusted by the belt and pulley arrangement. As per the need, it can be adjusted with the rearrangement of the belt with the pulleys. But speed of the motor is predefined with the diameter of pulleys, this is where our permission in order to change the speed gets completed.

Working:

The supply to the machine is turned OFF and the spring load is reduced to zero. Then the bolts in the clamping mechanism are loosened and the specimen is loaded in to it. The bolts are then tightened to ensure that the specimen does not loosen during the operation of the machine. The required load is set on the spring load by adjusting the nut below the spring load mechanism and the supply is turned ON. The digital counter is reset to zero and the machine is turned ON. After a certain period of time the specimen will fail and the digital counter will stop, then the machine is turned OFF. And the failed specimen is removed and a new specimen is loaded and the test is repeated for different values of spring load.

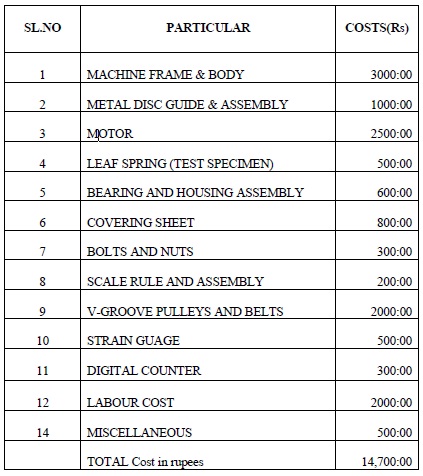

Cost Estimation of the Project

Scope for Future Work:

The project that is seen today is a conceptual setup. This setup was to test the fatigue life of composite leaf springs, on which many researches and developments are going on. The future scope of this project is seen to be very vast among which It can be modified for various testing parameters. Presently the accuracy of output of the machine depends on strain gauge reading, it can be improved in future by advanced micro fracture detecting techniques.

Conclusions

When fatigue stress is induced on a material due to theaction of force reversing and fluctuating, a failure known as fatigue failure takes place. The study and test conducted so far shows that fatigue failure cannot be predicted accurately since material failure under fatigue are affected not by just reversal loading alone but also the number of revolution (cycle per minute) and fluctuating stress and other factors such as temperature, atmospheric condition, both internal and external defect on material subjected under fatigue stress. Such defect includes notch, inclusion, stressconcentration and non-homogeneity.

Blazingprojects Mobile App

📚 Over 50,000 Project Materials

📱 100% Offline: No internet needed

📝 Over 98 Departments

🔍 Software coding and Machine construction

🎓 Postgraduate/Undergraduate Research works

📥 Instant Whatsapp/Email Delivery

Related Research

Optimization of Production Line Layout using Simulation Techniques in an Automotive ...

The project titled "Optimization of Production Line Layout using Simulation Techniques in an Automotive Manufacturing Plant" focuses on enhancing the ...

Optimization of production scheduling using advanced algorithms in a manufacturing e...

The project topic, "Optimization of production scheduling using advanced algorithms in a manufacturing environment," focuses on enhancing the efficien...

Application of Lean Six Sigma in Improving Manufacturing Processes in the Automotive...

The project topic, "Application of Lean Six Sigma in Improving Manufacturing Processes in the Automotive Industry," focuses on the implementation of L...

Optimization of Manufacturing Processes using Artificial Intelligence Techniques in ...

The project topic "Optimization of Manufacturing Processes using Artificial Intelligence Techniques in Industrial and Production Engineering" focuses ...

Implementation of Lean Six Sigma in a Manufacturing Process for Quality Improvement ...

The project topic, "Implementation of Lean Six Sigma in a Manufacturing Process for Quality Improvement and Waste Reduction," focuses on the applicati...

Optimization of Production Line Layout Using Simulation Techniques in a Manufacturin...

The project topic "Optimization of Production Line Layout Using Simulation Techniques in a Manufacturing Industry" aims to address the critical aspect...

Optimization of Production Scheduling in a Manufacturing Environment using Machine L...

The project "Optimization of Production Scheduling in a Manufacturing Environment using Machine Learning Algorithms" aims to address the challenges fa...

Implementation of Lean Six Sigma in a Manufacturing Industry to Improve Production E...

The project topic "Implementation of Lean Six Sigma in a Manufacturing Industry to Improve Production Efficiency" focuses on the integration of Lean S...

Implementation of Lean Manufacturing Techniques in a Manufacturing Company to Improv...

The project topic "Implementation of Lean Manufacturing Techniques in a Manufacturing Company to Improve Productivity and Quality" focuses on the appl...